Gas turbines

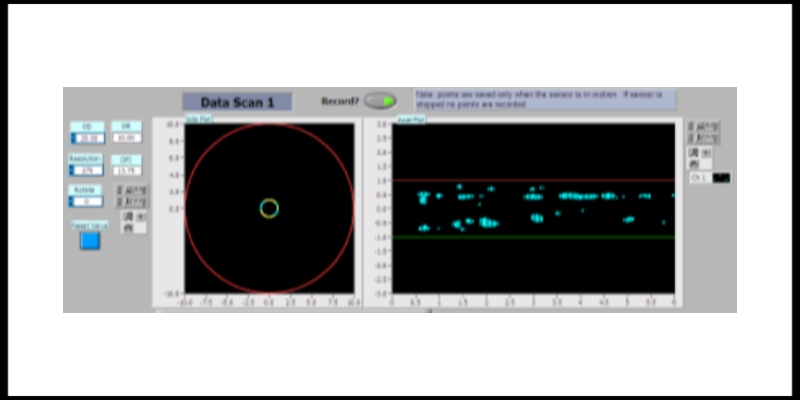

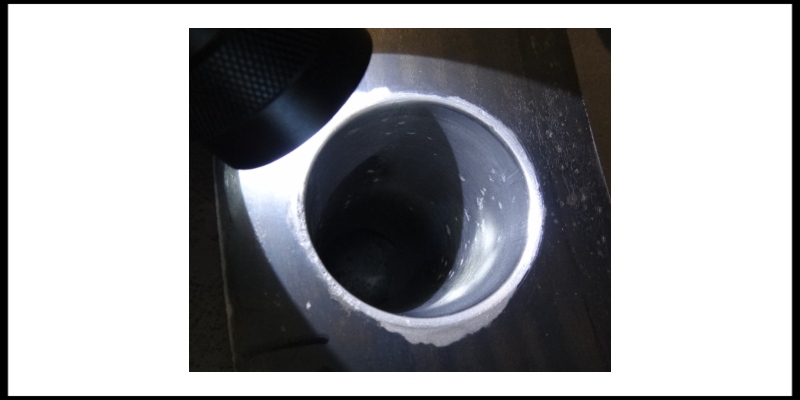

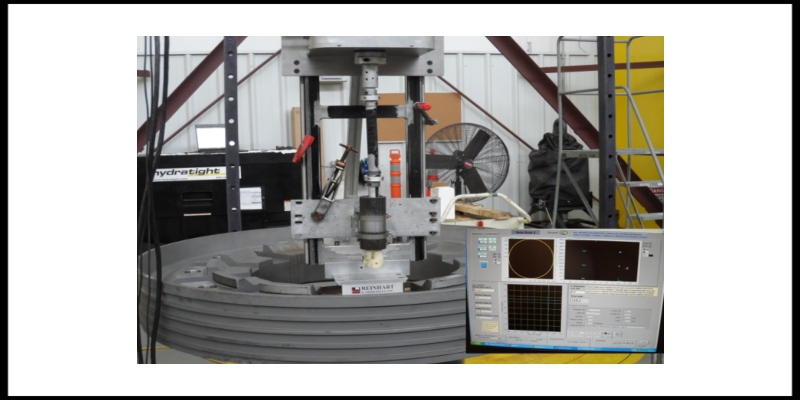

Boresonics

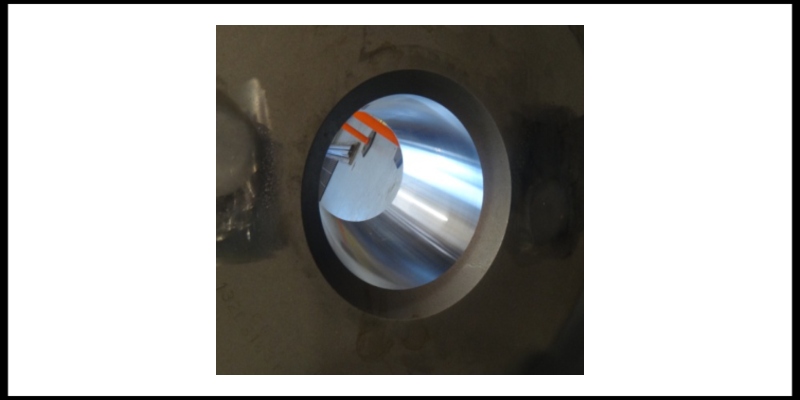

The Reinhart & Associates, Inc. (R&A) system B-SURE® (Boreside Surface and Ultrasonic Rotor Examination) originally developed for boresonic examination of hollow steam turbine and generator rotors is also used for the boreside examination of combustion or gas turbine disks bores, compressor wheel bores, and spacer bolt holes. The boresonic examination takes place at specialized repair shops where the gas turbine is completely disassembled for major repairs or life extension procedures. The examination of the turbine disk bore or compressor wheel bore consists of power honing, diameter measurements, boreside visual testing, boreside automated Eddy current testing, and boreside ultrasonic testing. The bolt holes of the turbine disks are examined using visual and Eddy current testing only.

Remote visual testing

Remote visual testing (RVT) of internal cavities of a gas turbine is routinely done in-situ or with the rotor removed from the casing. The RVT documents internal surface condition such as oxide scale formation, corrosion, mechanical damage, bolt nut condition, etc.

Disk dovetails wet fluorescent magnetic particle testing

For gas turbines compressor wheels and turbine disk dovetails that are made of ferromagnetic are examined using wet fluorescent magnetic particle testing (WFMT) to detect surface flaws.

Disk serrations (dovetails) eddy current testing

The ET examination of gas turbine disk serrations is sensitive to the detection of surface defects that may occur in the high stressed areas of the serrations. The ET examination is performed along the length of each serration and on both faces of the serrations i.e. inlet and exhaust faces.

Phased array ultrasonic testing (PAUT) of bolt threaded ends & UT of bolt

The accessible threaded ends of the through bolts of both the compressor and turbine are examined using PAUT. The PAUT technique examines all the threads for surface and volumetric indications but in particular the first three threads that engage most of the bolt load. The through bolts are also examined using conventional UT to interrogate the length of the bolt for bulk defects.

Turbine disk hardness measurements

The turbine disk accessible areas with the rotor in-situ are tested using a portable hardness tester. The hardness data collected is used to monitor the disks material condition and to detect any trends that may indicate material degradation as a function of service time.

Turbine disk surface replication

Surface replication of turbine disks is used to monitor material degradation by examining the material for gradual changes in microstructure, micro cracking, or heat related damage such as creep voids.